White paper:

Computer-Assisted Design of Sustainable Syntheses of Pharmaceuticals and Agrochemicals from Industrial Wastes

Adapted from

P. Le Pogam, N. Papon, M. A. Beniddir, V. Courdavault, ChemSusChem 2022, 15, e202201125. https://doi.org/10.1002/cssc.202201125

Published with the courtesy of Wiley.

Chemists are seeking to more efficiently use the remaining chemical resources from industrial synthetic pathways, thereby increasing sustainability and overcoming supply chain bottlenecks of precursor molecules. Here, a state-of-the-art computational synthesis-based approach identifies synthesizable molecules of commercial interest that can use one or more common waste products from large-scale industrial processes as substrates or precursors. Its algorithmic ranking of synthetic strategies incorporates metrics of sustainable chemistry.

Introduction

During recent decades, chemists are seeking to improve sustainability of large-scale industrial synthetic processes by repurposing one or more of the waste products. Analogous to computer-based synthetic strategies in analytical chemistry, recent computer algorithms are compiling lists of end-of-pipe industrial waste that may serve as substrates or precursors during novel synthetic pathways of pharmaceutical-relevant products. This process is called the circular chemistry concept or sustainable chemistry.

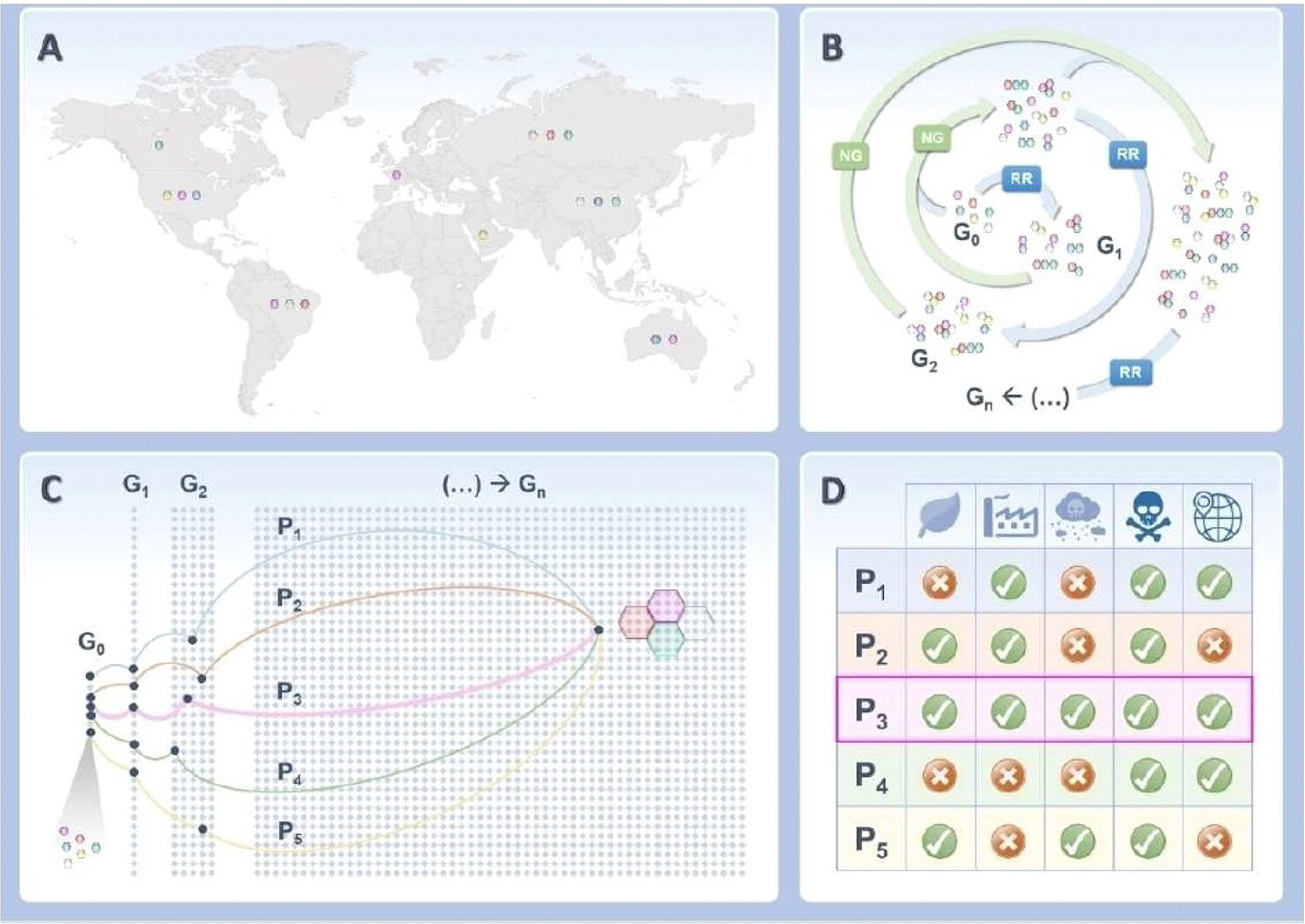

Sustainability Characteristics ranked in silico transformation module

Even a small set of substrates can generate synthetic pathways for millions of feasible compounds. Thus, the computer-based programs need to rank the synthetic strategies for simplicity and for sustainability. An in silico transformation module learns from 10,000 plus reactions in an in-house collection that includes information on incompatible structural motifs, admissible substrates, suggested conditions, reagents, and typical conditions. Additional information used for developing a synthetic pathway includes suggested solvents, usual temperature range, ability of reactions to be performed in tandem, renewable resources, abundance of commercially available waste product(s) for reagents, geographical origin of industrial chemical waste, and avoidance of problematic solvents according to health or environmental criteria. Figure 1 provides an overview of artificial intelligence (AI) programs and pertinent metadata considered during development of putative synthesizable products that can reuse the industrial waste as building blocks or substrates and increase chemical sustainability.

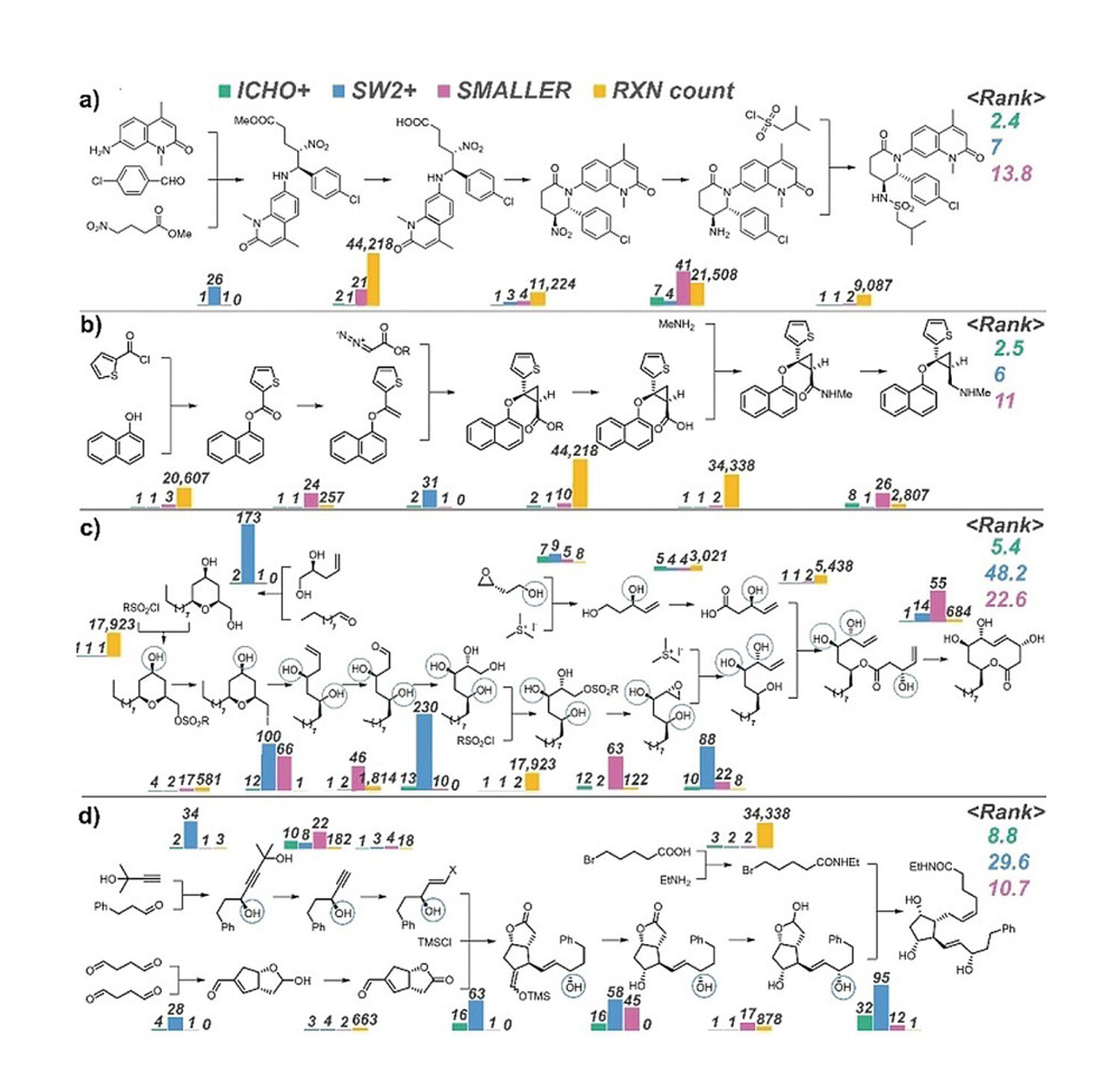

Within the ICHO and SW programs, the inclusion of learning from the heuristics expert chemical rules (ICHO+, SW+) only marginally improved the efficiency of the synthetic plans. Limiting the SW programs to product-fitting reactions (SW2, SW2+) improved their performance. However, ICHO+ remained the highest ranked pathway, likely due to its additional knowledge of substrates.

The performance of the three types of programs were evaluated on developing synthetic pathways involving both experimentally established reactions and relatively advanced synthetic pathways. Synthetic plans for four complex products developed by the ICHO+, SW2+, and SMALLER programs are compared in Figure 2. ICHO+ ranked highest for the synthetic plans for the four products: the BRD 7/9 inhibitor, the serotonin–norepinephrine reuptake inhibitor (+)-synosutine, the natural product seimatopolide A, and the prostaglandin analogue bimatoprost.

For example, the AllChemy-based platform also contains an AI algorithm that can predict molecular properties of the synthetic compounds. As a second example, SYNTHIATM Retrosynthesis Software can efficiently explore the most cost-effective and innovative synthetic routes to produce the target molecules. Chemists can use filter options and art visualization to optimize the synthetic routes of target compounds. SYNTHIATM allows customization of search parameters to prevent or promote specific reactions, reagents, or classes of molecules, including desired stereoisomers. It can generate a list of commercially available starting materials while guaranteeing the integrity and confidentiality of clients’ data with ISO/IEC 27001 information security certification.

Power of AI Program

Le Pogam and colleagues describe Wolos et al.’s article [1] that used the Allchemy-based program to identify synthesizable pharmaceutical-relevant products or agrichemicals from 189 chemical wastes. Each synthetic generation of the algorithm compares the synthesized product(s) with the initial substances and those obtained in intermediate generations (Fig. 1B). Since the goal is to facilitate synthesis of high-value compounds from the specific waste in an efficient time frame, researchers can improve efficiency in the next analytic/synthetic generation by retaining small compounds for use as building blocks and molecules with structural similarity to the target synthetic compound.

The AI-created networks usually provide a high combinatorial repertoire of diverse reactions that can lead to the synthesis of the target product or drug (Fig. 1C). The operator should set a threshold of less than 100,000 compounds to maintain reasonable calculation timeframes. The AI-created networks are queried after each generation for various process variables that directly affect the safety of the synthetic process, its efficiency, cost, and sustainability.

A meta-score compiles the attributes of the synthetic pathway and its ranking reflects also penalties for undesired attributes in at least five categories which are scored from 1 (most desirable) to 10 (least desirable or most harmful) (Fig. 1D). Penalties are provided for use of harmful or problematic reagents or solvents since the use of health and environmentally friendly reagents, substrates, solvents and building blocks are preferred. Penalties are levied for challenging reaction conditions such as extreme temperatures or experimental difficulties like intense exo- or endo-thermic reactions. Penalties also are levied for producing more by-products and waste, which is referred to as low atom economy and is often measured as process mass intensity (PMI). The preferred reactions produce the least amount of waste or by-products. PMI compiles the mass of all material (reagents, catalysts, reactants, solvents, and workup chemicals) in the synthetic process relative to the yield of the isolated product. Lastly, a local origin of repurposed industrial waste product for building blocks or substrates is preferred to reduce transportation costs and supply chain disruption. Thus, a penalty will be levied for disparate geographical locations of the industrial waste and the putative user.

AI analysis with 189 waste products and seven rounds of chemical transformations provided in silico synthetic pathways for 300 million compounds, including 69 drugs and 98 agrochemicals. Wolos et al. [1] identified novel synthetic pathways for several targets that use waste products from the same origin in mostly benign conditions with relatively few steps. Interestingly, the described program can broaden its development of synthetic pathways to several of the most prescribed medicines by adding 1000 basic reagents to the 189 available wastes. Wolos et al. [1] have validated several of these computer-predicted pathways experimentally [1].

Summary

The described AI synthesis tools provide opportunities to predict synthetic pathways of diverse compounds from a set of any widely available precursors, including industrial waste products. The current workflow incorporates the expansive knowledge of organic chemical reactions and its associated metadata that can be assessed for its compliance with sustainability and green chemistry metrics at each transformation. These additional checks help ensure that the proposed synthetic pathway for a target compound has a high probability of industrially realistic yields and provides sustainable access to its precursors. This refined AI workflow expands the retrosynthetic chemists’ a priori network of substrate-based transformations to alternate novel synthetic pathways that may incorporate locally sourced industrial waste products.

References

[1] Wołos, A. et al. (2022). Computer-designed repurposing of chemical wastesinto drugs. Nature. DOI: 10.1038/s41586-022-04503-9.